1.Overview

This machine is a small type of lubrication pump, which can be directly installed on the wall or frame of the machine. The handle can be manually pulled by humans to discharge the process grease. It can be combined with a dual-line distributor to form a manual centralized lubrication system. Lubrication point supply fixed quantity of grease; suitable for low frequency (usually more than 8 hours interval between oil supply), piping (D N15) length of less than 50 meters, lubrication point of less than 80 single-machine small equipment, as a centralized lubrication supply Grease delivery device.

2.Technical parameters

The medium used is a grease (NLGI 0 # ~ 1 #) with a penetration of not less than 310 ~ 385 (25 ° C, 150g) 1 / 10mm, and the applicable ambient temperature is + 10 ° C to + 40 ° C

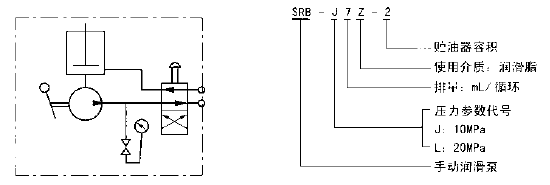

3.Principle diagram

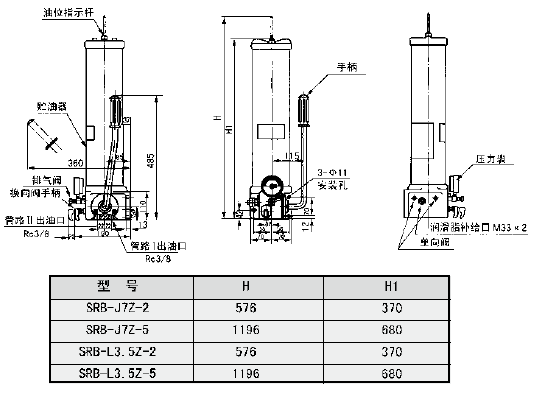

4.Dimensions

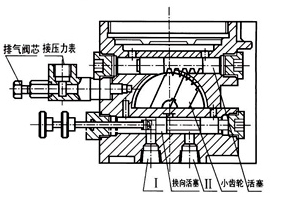

5.action description

The grease supply of the manual lubrication pump is realized by an artificial swinging handle, which reciprocates the oil supply plunger with a rack through a pinion. When the plunger is in the right end limit position, the oil pressure in the right end chamber is ended, and the oil absorption in the left end chamber is completed. When the handle is swung and the plunger moves to the left, first close the suction chamber of the left chamber, squeeze the grease to open the one-way valve, and enter the oil supply main circuit Ⅱ through the diverter valve flow path to discharge; The volume increases to form a vacuum, and the degree of vacuum gradually increases. When the plunger moves to the left extreme position, the right chamber suction port opens. Under the action of the atmosphere, the grease is sucked in, and the above action is reversed, and the grease opens in one direction. The valve enters the oil supply main line JJ through the diverter valve flow passage and is discharged. The reversing in the oil supply process is realized by the reversing of the reversing valve. When the selector valve knob is advanced, the grease is discharged from the main pipe II, and when the selector valve knob is pulled out, the grease is discharged from the main pipe I.

7.Operation method

1. Push the reversing valve knob to the extreme position, and the oil supply supervisor Ⅱ supplies oil.

2. The swing handle moves back and forth, and the pressure gauge pointer fluctuates, which proves that the series distributor is supplying oil.

3. The pressure gauge on the pump indicates that the pressure value keeps rising, which proves that all the actions of the system distributor are completed.

4. Pull out the switch valve knob to the extreme position, and the oil supply supervisor I supplies the oil. Operate according to 2 and 3.

5. Remove the pipeline pressure and switch to the oil supply supervisor Ⅱ. Prepare for the next working cycle. Turn the handle to the vertical position.

8.Instructions for use

1. The manual lubricating pump should be installed vertically. There should be space for the indicator rod to rise and replenish the operation of the pump above and around the pump. When it is installed outdoors or in harsh environments, the pump should be placed in a protective cover.

2. When there is no grease in the oil reservoir, do not operate the handle, and the oil level should be replenished in time.

3. To fill the oil reservoir with grease, you must use a dedicated manual or electric refueling pump to fill it from the filler port.

4. The use pressure of the pump must not exceed the nominal pressure of the pump.

5. The filter at the pump filler should be regularly checked and cleaned.

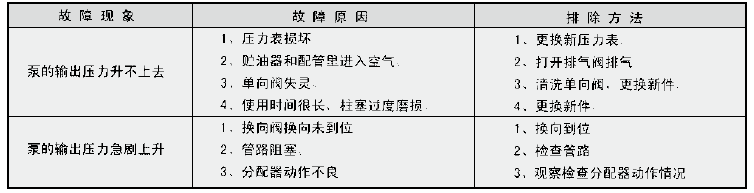

9.Common fault handling

Address: No.010 Xinglong Road, Huilong Industrial Park, Qidong City

Hotline:0513-83637668

Company Fax:0513-83637098

After sales service:0513-83635700

URL:www.qdhsrh.com

Website :en.qdhsrh.com

E-mail:qd3637668@163.com

Scan to learn more