1. Overview

This type of manual lubricating pump is a small single-line lubricating pump that is manually pulled by the handle to discharge grease. It can be directly installed on the wall or frame of the machine. Directly connected to the single-line distributor to form a single-line manual centralized lubrication system.

It is suitable for single-line small-scale equipment with low lubrication frequency (usually the lubrication interval is more than 4 hours), the length of the piping (D N15) does not exceed 50 meters, and the lubrication point does not exceed 100. Device.

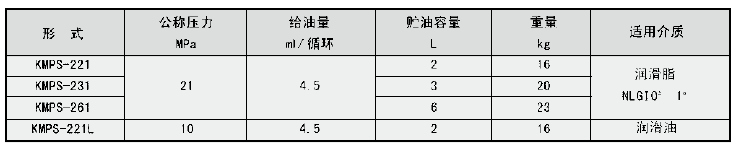

2.Technical Parameters

3.Principle of action

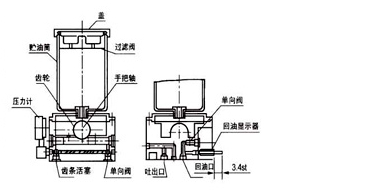

The manual lubricating pump is a manual swinging handle, and the rack piston is reciprocated by the gear to achieve external oil supply. When the piston is at the extreme position shown in the figure, the grease is sucked in through the suction port and fills the right cavity of the piston. When the piston moves to the right, the sucked grease is pushed up by the check valve under the action of the oil pressure and sent to the outlet. Drain outward. When the amount of oil returned to the oil return indicator from a metering port of the main distributor in the system reached 3.2m L, all the indicating rods were extended, proving that all the lubrication points of the system had obtained the required amount of lubricant, and stopped Operate the handle and press the indicator rod inward to prepare for the next cycle. The grease in the indicator is returned to the oil storage tank through the check valve.

4.Operation method

1. Push the rod of the oil return indicator.

2. The swing handle moves back and forth, and the pressure gauge pointer fluctuates, which proves that the system distributor is performing the oil feeding action.

3. The indicating rods of the oil return indicator are all extended, proving that the system distributor has completed a lubrication cycle for oil.

4. Push the return rod of the oil return indicator to prepare for the next cycle.

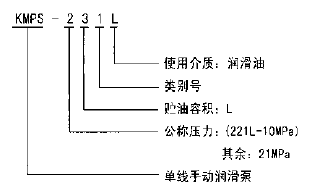

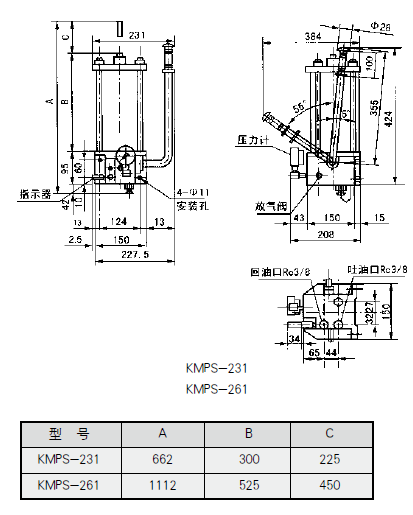

5.Model Description

6.Instructions for use

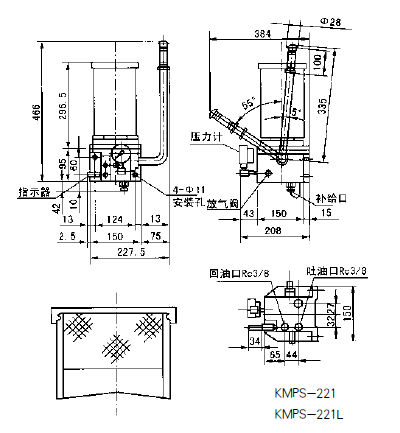

1. The manual lubricating pump should be installed vertically, and there should be space above the pump and around the pump for indicating rod operation and replenishing. When installing outdoors or in a harsh environment, the pump should be placed in a protective cover.

2. When there is no grease in the oil reservoir, it is not allowed to operate the handle, and the oil should be replenished in time.

3. For filling fat into the oil reservoir, it must be filled from the fat filling port using a manual or electric fat pump.

4. The safety valve has been adjusted to the nominal pressure before leaving the factory. No arbitrary adjustment is allowed.

5. The function of the oil return indicator on the pump is that the operator can know the oil supply status of the process lubrication system by observing the movement stroke of the indicator piston indicating rod. When using, first calculate the required oil supply for each lubricating part, configure the distributor, and connect an extra oil outlet on the main distributor to the oil return port of the manual lubrication pump to return the grease to the instruction In the device, if the total amount of returned oil reaches 3.28ml, the piston rod of the indicator is fully extended, indicating that each lubrication point has completed a cycle of oil supply as required. The oil supply should be stopped and the indication of the oil return indicator should be Pole advance.

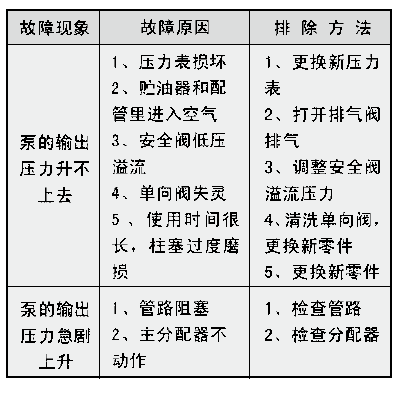

7.Common fault handling

Address: No.010 Xinglong Road, Huilong Industrial Park, Qidong City

Hotline:0513-83637668

Company Fax:0513-83637098

After sales service:0513-83635700

URL:www.qdhsrh.com

Website :en.qdhsrh.com

E-mail:qd3637668@163.com

Scan to learn more