1.Overview

The SGQ series double-line oil feeder is suitable for a double-line dry oil centralized lubrication system with a nominal pressure of 10M Pa, as a metering oil supply device. Under the action of the alternate oil supply pressure of the two oil supply pipes, the piston is fed by the oil supply pressure to complete the function of quantitatively distributing grease to each lubrication point.

SGQ wire to the oil has two kinds of the one-way and two-way structure of oil out of the oil. The one-way oiler has only the lower oil hole. When the piston is drained in the forward and reverse directions, the lower oil hole supplies grease to the lubrication point. The two-way oiler has upper and lower oil holes. The piston When the oil is discharged in the forward and reverse directions, the upper and lower oil supply holes alternately supply grease to the lubrication point. The lubricator can directly observe the working condition of the lubricator from the action of the indicating rod. The process is lubricated, and the oil supply amount of each oil port can be easily adjusted within the specified range by adjusting the screw.

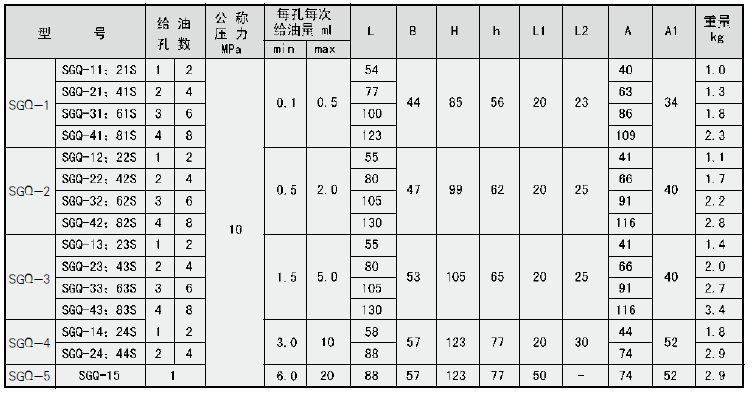

2.Technical Parameters

The medium used is grease (NLGI 0 # ~ 2 #) with a penetration of not less than 265 (25 ° C, 150g) and 1 / 10mm, and the working environment temperature is -10 ° C to 80 ° C

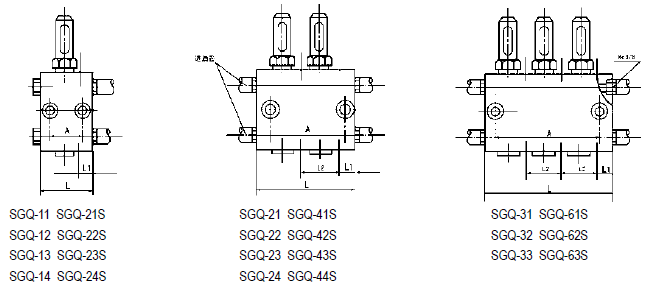

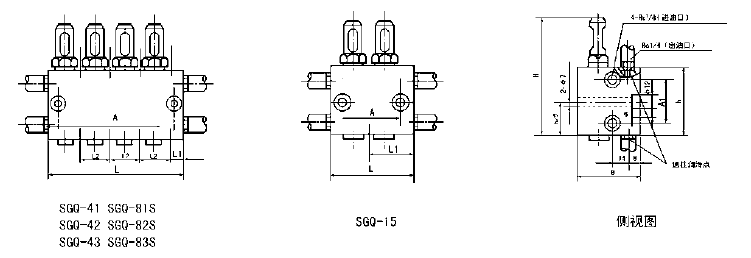

3.Outline

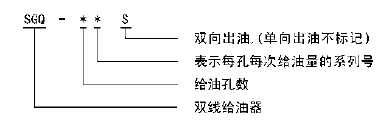

4.Model Description

5.Instructions for use

1. The specified medium must be used in the specified environment.

2. Use in dusty, humid, and harsh environments.

3. The two oil inlets of the oil feeder are respectively connected to two oil supply pipes, and both sides are through. When one side of the oil inlet is not in use, R3 / 8 screw plugs should be used to block it.

4. The oil feeder is preferably installed in parallel in the system, and the oil supply pipe and the distributor can be connected on the left or right; second, the series installation is used, and the maximum number of serial connections is not allowed to exceed three.

5. The adjustment of oil supply is to unscrew the locking screw on the stopper first, and then adjust the adjustment screw. The oil supply can be adjusted within the range of large and small oil supply according to the actual needs of the lubrication point. Adjustment should be performed with the indicator rod retracted. After adjustment, tighten the locking screw.

6. The screw plug at the two ends of the oiler piston must not be removed; if there is a leak, tighten the screw plug or replace it with a new seal.

7. If the number of lubrication points of the machine is odd, you can remove the partition member in any of the lower oil outlets, and then plug the upper oil outlet with a screw plug, and you can use it.

6.Common fault handling

1. The oil feeder does not work.

Check the oil supply pipe for pressure oil delivery, whether the unloading oil pipe is unblocked, whether the lubrication point is blocked, whether impurities have entered the oiler, causing the piston hole to be pulled, etc., and it can be checked after elimination.

2. There is oil leakage at the stopper indicating rod.

Remove the stopper body, check whether the seal ring is used for a long time or exceeds the specified ambient temperature, and replace the seal ring after finding out.

7.download Google

The installation and use of the oiler with an ambient temperature> 80 ° C must be specified in the order contract in order to supply high temperature resistant seals.

Address: No.010 Xinglong Road, Huilong Industrial Park, Qidong City

Hotline:0513-83637668

Company Fax:0513-83637098

After sales service:0513-83635700

URL:www.qdhsrh.com

Website :en.qdhsrh.com

E-mail:qd3637668@163.com

Scan to learn more