I. Conditions of use

The rotary kiln supporting wheel should be installed parallel to the center line of the kiln body. The kiln body is placed at an angle and has a tendency to slide under its own weight. The hydraulic thrust block hydraulic station is used to make the kiln body at the expected speed (usually about 2 ~ 3m / h) Force upward movement and controlled descent to effectively ensure uniform contact and wear between the belt and the idler to save the workload of adjusting the idler.

The normal upstream and downstream travel of the hydraulic gear wheel is ± 10m m. When the upstream and downstream travel reaches 15m m, an alarm signal should be issued. When the upstream and downstream travel reaches the limit stroke (± 30m m), the main motor should be stopped immediately. The power supply allows a small change of ± 2mm to the above control stroke by adjusting the position of the limit switch.

II.Technical parameters

1. Working pressure: 4 ~ 10MPa

2. Nominal flow rate: 1.14L / min

3. Filter accuracy: 20μm

4. Fuel tank volume: 0.11m3

5. Electric heater power: AC220V, 1kW

6. Motor power: 0.75kW

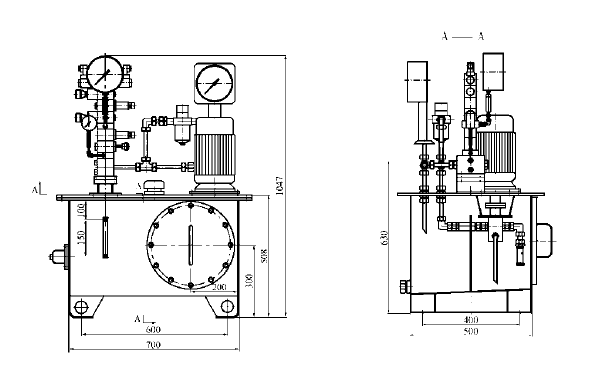

III.Dimensions

IV.Working principle

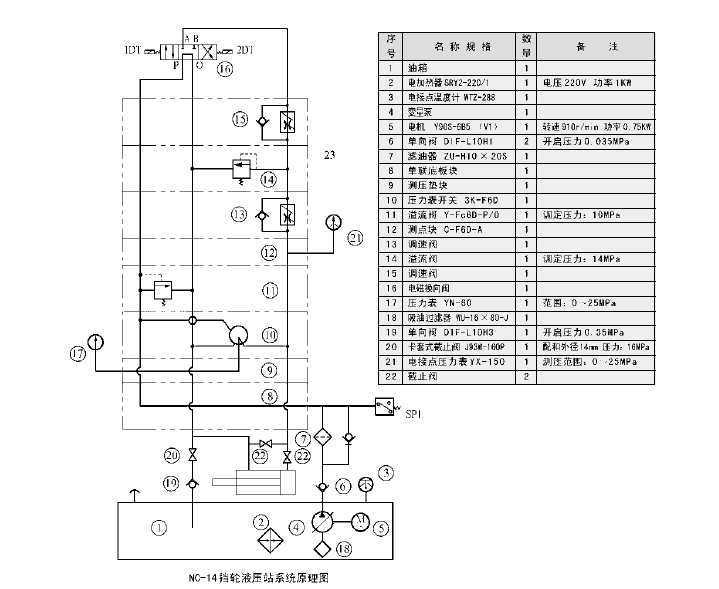

The NC-14 block wheel hydraulic station is a power unit that controls the action of the hydraulic block wheel of a rotary kiln. Its working principle is shown in the following figure:

When the kiln body moves downward from the zero position (that is, the position where the center line of the travel switch and the center line of the belt coincide), a contact in the process lubrication travel switch box is activated, the oil pump 4 starts, and the electromagnetic induction of the directional valve 16 Ring A is connected, and the pressure oil enters the hydraulic cylinder through the left valve of the reversing valve via the speed regulating valve 15. At this time, the piston of the hydraulic cylinder pushes the blocking wheel to force the kiln body to move upward under the action of the pressure oil.

When the kiln body moves to the upper limit, a contact in the travel switch box is activated, the oil pump 4 stops, the electromagnetic induction coil B of the directional valve 16 is turned on, and the oil in the hydraulic cylinder passes through the speed regulating valve 13 and the directional valve. 16 Right position return oil tank. When the kiln body moves down by its own weight, a contact in the stroke switch box moves, the electromagnetic induction coil B of the directional valve 16 is opened, the oil pump 4 starts, and the directional valve 16 The electromagnetic induction ring A is turned on, and the hydraulic cylinder piston pushes the blocking wheel to force the kiln body to move upward under the action of the pressure oil.

If the kiln body goes up or down to the extreme position under abnormal conditions, the contacts in the travel switch box act, and an alarm is issued: and the electromagnetic reversing valve is reversing.

Address: No.010 Xinglong Road, Huilong Industrial Park, Qidong City

Hotline:0513-83637668

Company Fax:0513-83637098

After sales service:0513-83635700

URL:www.qdhsrh.com

Website :en.qdhsrh.com

E-mail:qd3637668@163.com

Scan to learn more