I. Use

Applicable to most of the mechanical processing, widely used in the automotive, machine tool, motor, bearing industry and other mechanical processing, large-scale industries such as compressors. Suitable for filtering rolling fluids in steel plants.

II.Function introduction

Fine filtration and control.Select different filter cloths to achieve the required accuracy (15-80μmLarge flow applicable range (15-150m3 / h)

The equipment has functions of degreasing, aeration, bottom flushing, chain flushing, pressure regulation, and holiday circulation, which greatly prolongs the life of the emulsion, thereby reducing the emissions and protecting the environment.

High-quality, clean coolant can improve the quality of the workpiece, reduce the rate of rejects, and extend the service life of the knife and grinding tool.

The vacuum chamber can be cleaned automatically during the holiday cycle and when the coolant is changed.

The heat exchange system keeps the output temperature of the coolant constant at the set temperature to ensure the machining accuracy of precision parts.

The filtration system is controlled by the PIC. There are four modes: automatic, semi-automatic, manual, and holiday cycle. Safe and reliable operation.

If the DZG series filter is equipped with a coarse filter, it can improve the filtration accuracy and reduce the consumption of filter media.

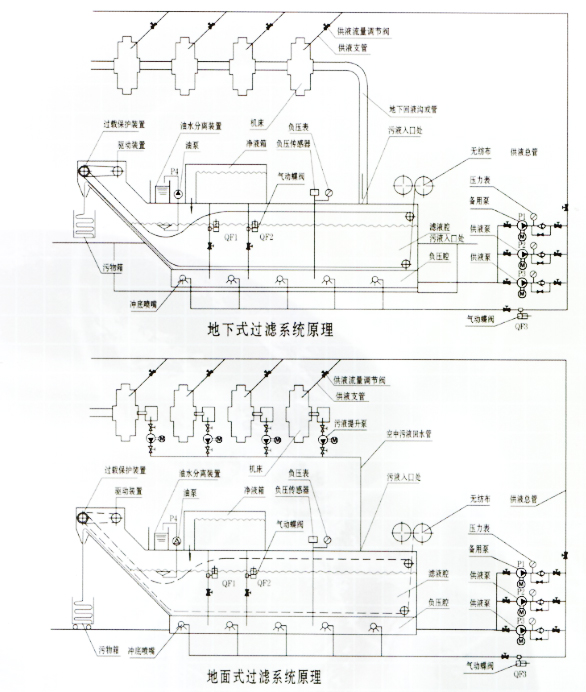

III.The installation form

Underground: Flow to the filtration system through underground pipelines or trenches.

Ground type: Each machine tool's coolant flows to the pit through an underground pipeline or trench and is lifted by the pump to the filtration system; each machine tool is equipped with a water tank and a lift pump, which are then lifted by the pump to the filter system.

IV.The outline diagram

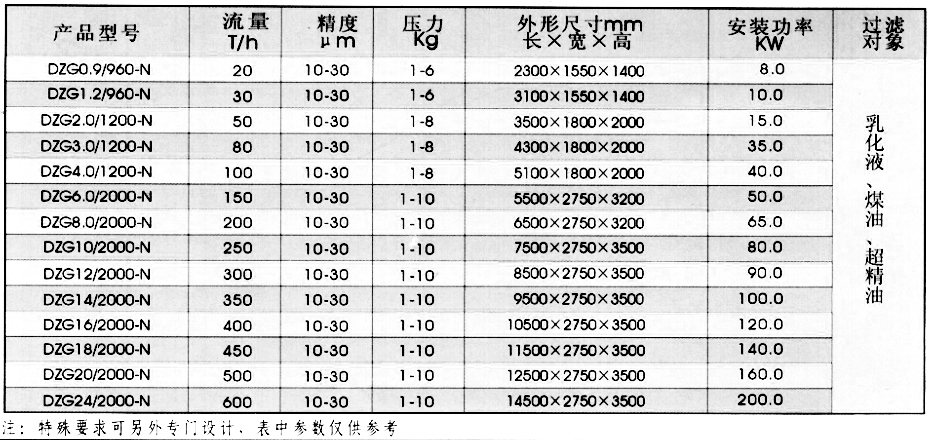

V.Specifications and technical parameters

Address: No.010 Xinglong Road, Huilong Industrial Park, Qidong City

Hotline:0513-83637668

Company Fax:0513-83637098

After sales service:0513-83635700

URL:www.qdhsrh.com

Website :en.qdhsrh.com

E-mail:qd3637668@163.com

Scan to learn more