It lubricates certain points with an accurate amount of grease and predetermined intervals, and has real-time monitoring and fault removal functions.

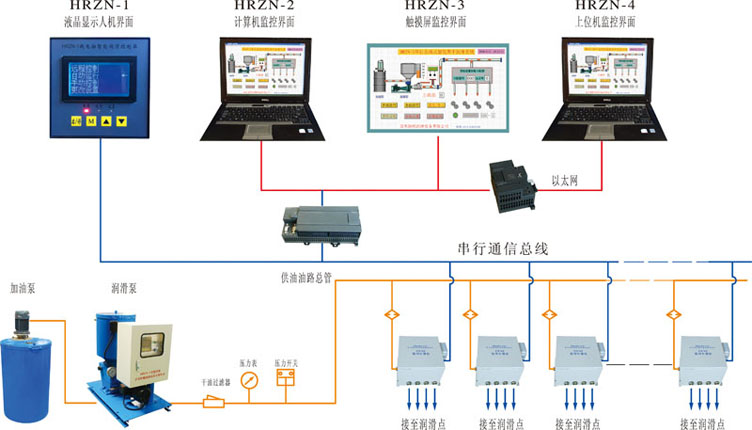

The system uses smart lubrication as its main control element and uses a touch screen as a text display. The pressure sensor is a sensor made in the United States, which can monitor the system pressure in real time, and can be connected to the monitoring system of the upper computer through the Internet to achieve remote control and real-time monitoring. Therefore, the lubrication conditions will become clear. The operator can adjust the grease supply parameters through the text display / touch screen according to the lubrication requirements of each point to meet the different requirements of each point. The grease supply parameters can also be adjusted by the monitoring system of the upper computer in the central control room.

The system operates in a stable and reliable manner, and it is easy to adjust the amount of oil (grease) and find the point of failure. The maintenance work is greatly reduced, the labor is greatly reduced, and environmental pollution and waste of grease are avoided. It can also increase the life of the system and increase overall smart lubrication efficiency. The grease supply parameters can also be adjusted by the monitoring system of the upper computer in the central control room. The system operates in a stable and reliable manner, and it is easy to adjust the amount of oil (grease) and find the point of failure. The maintenance work is greatly reduced, the labor is greatly reduced, and environmental pollution and waste of grease are avoided.

Address: No.010 Xinglong Road, Huilong Industrial Park, Qidong City

Hotline:0513-83637668

Company Fax:0513-83637098

After sales service:0513-83635700

URL:www.qdhsrh.com

Website :en.qdhsrh.com

E-mail:qd3637668@163.com

Scan to learn more