1.Conditions of Use

Applicable to a two-line centralized lubrication system with a nominal pressure of 20 MPa as a metering oil supply device. Under the action of the alternate oil supply pressure of the two oil supply pipes, the piston is directly pushed by the oil supply pressure to complete the lubrication The function of point-dispensing grease.

SDPQ-L series one-way oil distributor has the oil inlet at the bottom. The forward and reverse movements of the distributor piston discharge oil from the same oil inlet. Each time the system works, the oil outlet is drained once.

SSPQ-L series two-way oil distributor has oil supply ports on the front and bottom. The distributor piston forward and reverse movements respectively discharge grease from the front and bottom oil supply ports. Compared with the SDPQ type distributor, the oil supply port is doubled. The front right feed port is prefabricated under the oil port, and the two ports are combined into one plug. It is easy to change to an odd number of oil outlets, and the system piping is simple. The SSPQ-L2, 3, and 4 series of distributors have the same external installation dimensions for the same number of oil ports, which is easy to change and replace.

2.Technical parameters, dimensions

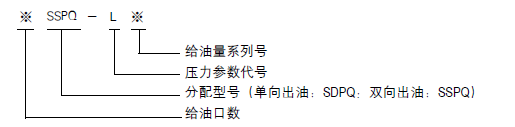

3.Model Description

4.Action description

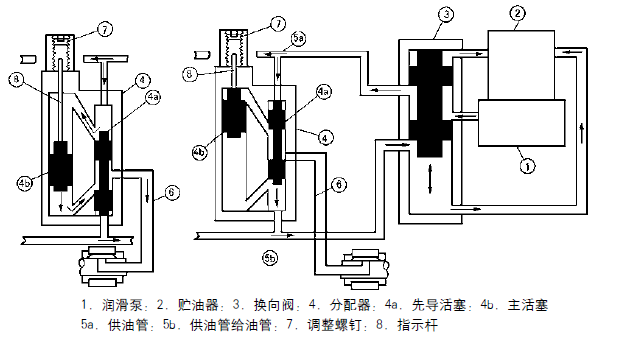

The two-line distributor has two oil inlets, which are connected to the 5a.5b oil supply pipes respectively. When one of them is supplied by the lubrication pump, the other one is opened to the oil reservoir.

As shown in the figure above, the grease sent by the pump is transported to the distributor 4 through the oil supply pipe 5a, enters the upper part of the pilot piston 4a to pressurize, and presses down the pilot piston 4a. At this time, the lower part communicates with the fuel supply pipe 5b and unloads. Dutch. With the downward movement of the pilot piston 4a, the upper cavity of the main piston 4b communicates with the upper cavity of the pilot piston, the lower cavity of the main piston communicates with the oil outlet, the supplied lubricant enters the upper cavity of the main piston, and pushes the main piston downward. The process lubricant in the lower cavity is pressed to the lubrication point through the oil feeding pipe 6 to complete a cycle of oil feeding action.

Switching to the oil supply pipe 5b to start the oil supply operation of the second cycle, the distributor piston reverses the aforementioned operation in the same order.

The oil supply port of each distributor is determined by the diameter and stroke of the main piston 4b. By adjusting the adjustment screw 7, the stroke of the main piston 4b can be changed to achieve a regulated range of oil volume.

The operating principle of the SSPQ-L series distributor is the same as above, and the oil supply pipes 5a and 5b respectively supply oil once, and the lower and front oil inlets respectively discharge oil once.

5.Instructions for use

1. The specified medium must be used in the specified environment.

2. The two oil inlets of the distributor are respectively connected to two oil supply pipes, and both sides are through. When the oil inlet on one side is not in use, the screw plug should be plugged. Plug the unused oil supply port (SDPQ series).

3. It should be equipped with protective cover when it is used in dusty, humid and harsh environment.

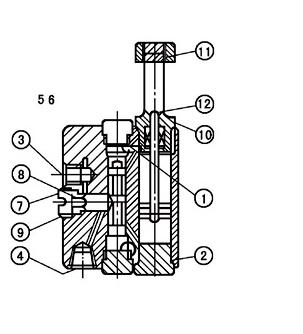

4. To adjust the oil quantity, turn the adjusting screw (11) on the stopper (10) to adjust the oil quantity within the range of the large and minimum oil quantity according to the actual needs of the lubrication point. Adjustment should be performed with the indicator rod (12) retracted. After adjustment, tighten the locking screw.

5. If the number of oil supply ports is an odd number, the screw plug (8) inside the screw plug (7) should be screwed out and plugged on the oil supply port (3), and then the screw plug (7) is reinstalled, so that the oil supply port (3) It communicates with (4), and the positive and negative movements of the piston are discharged from the oil supply port (4).

6. The two-line distributor is preferably installed in parallel in the system. The fuel supply pipe and the distributor can be connected on the left or right. Second, the serial installation method is used. The number of large series is not allowed to exceed three. Can be combined in series.

7. The surface in contact with the distributor should be smooth and flat, and the mounting bolts should not be over-tightened, so as to prevent deformation from affecting normal operation.

8. The screw plug at the two ends of the distributor piston must not be disassembled for any reason. If it leaks, it should be tightened or replaced with a new sealing gasket.

6.Common faults and troubleshooting methods

1. The distributor does not work.

Check whether the oil supply pipe is under pressure oil delivery, whether the lubrication point is blocked, whether the oil supply pipe is squashed, and whether there are impurities in the distributor that cause the piston hole to be pulled. Exclude after finding out.

2. There is oil leakage at the indicating rod of the limiter body.

Remove the stopper and replace it with a new oil seal. The oil seal may be aging or exceed the specified ambient temperature. Replace it after finding out.

7.Ordering instructions

1. The installation and use of the ambient temperature> 80 ℃ must be specified in the order contract, so that high temperature resistant oil seals are used when supplying.

2. When the corresponding outlets of SSPQ (DW) type distributors need to be merged, add a subscript after SSPQ when ordering, that is, SSPQ1 or DW- ※※ H; the final "H" when not combined is not taken.

Address: No.010 Xinglong Road, Huilong Industrial Park, Qidong City

Hotline:0513-83637668

Company Fax:0513-83637098

After sales service:0513-83635700

URL:www.qdhsrh.com

Website :en.qdhsrh.com

E-mail:qd3637668@163.com

Scan to learn more