I. Overview

YCK-P5 (original SG-A) differential pressure switch is suitable for two-line centralized lubrication system with a nominal pressure of 40MPa. It controls the reversing valve or monitors the lubrication system and uses the pressure difference between the two pipes to send out electrical signals. When the pressure difference reaches 5MPa, a signal is sent to control the reversing valve to reverse or monitor the lubrication system. It is generally installed at the extreme ends of the two main pipes of the terminal double-line centralized lubrication system.

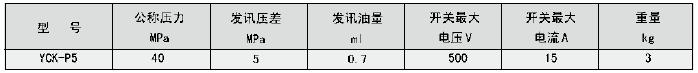

II.Technical Parameters

The grease used is a grease (NLGI 0 # ~ 3 #) with a cone penetration of not less than 220 (25 ° C, 150g) 1 / 10mm and a lubricant with a viscosity grade greater than N68.The working environment temperature is -20 ℃ ~ 80 ℃.

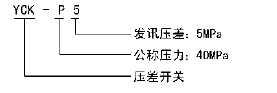

III.Model Description

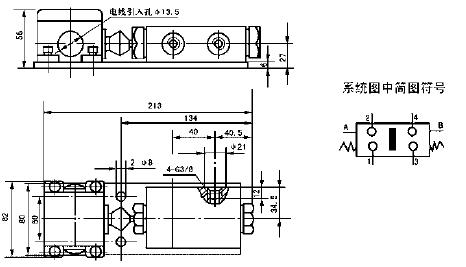

IV.Dimensions

V.Working principle

The valve body and the position switch of the differential pressure switch are assembled on a base plate. The dry thin oil grease enters the right cavity of the differential pressure switch valve piston from the main pipeline B under the pressure, and the main pipeline A is unloaded. Once the pressure difference between the two main pipes reaches 5M P a, the piston moves to the left against the spring force in the left cavity and pushes the travel switch to close the contacts 1 and 2 and sends a pulse signal to the system electrical control box to order the direction change. The valve is reversed. At this time, the main pipeline A is under pressure and B is unloaded. The piston is centered under the action of the spring in the two-end cavity. The system starts the second cycle of work. Once the pressure difference between the main pipeline A and B reaches 5 MPa, the piston moves to the right, the trip switch contacts 3 and 4 are closed, and the pulse signal reverses the directional valve in the system and starts Cycle work.

VI.Instructions for use

1. The differential pressure switch should be installed in a place that is ventilated, dry and easy to observe, and there is no interference from the movement mechanism.

2. The differential pressure switch is installed at the end of the main pipeline of the terminal dual-line centralized lubrication system. A double-line distributor must be installed at the back to prevent the grease in the differential pressure switch from aging, deterioration and solidification, which affects the sensitivity.

3. After connecting the travel switch, adjust the contact bridge to the neutral position and tighten the screws.

Address: No.010 Xinglong Road, Huilong Industrial Park, Qidong City

Hotline:0513-83637668

Company Fax:0513-83637098

After sales service:0513-83635700

URL:www.qdhsrh.com

Website :en.qdhsrh.com

E-mail:qd3637668@163.com

Scan to learn more