I.Conditions of Use

EM type electric directional valve is suitable for dry oil centralized lubrication system with a nominal pressure of 40M Pa. The pressure grease at the single line outlet of the dry thin oil lubrication pump is alternately sent through the main pipeline Ⅰ or Ⅱ to form a complete double Line terminal dry oil centralized lubrication system.

The reversing valve is an integrated reversing control device driven by a miniature AC motor and driving the eccentric link mechanism through a reduction gear to open and close the fuel supply pipeline or change the fuel supply direction; it is sensitive and sensitive, Quick opening and closing, reliable action, can be used in conjunction with the electric control box to automatically control the lubrication system.

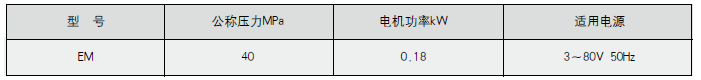

II.Technical Parameters

The medium used is a grease (NLGI 0 # ~ 3 #) with a penetration of not less than 220 (25 ° C, 150g) 1 / 10mm.

III.Working principle

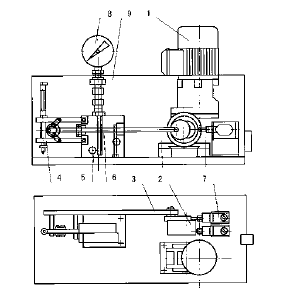

EM type electric directional valve is mainly composed of motor, reduction mechanism, eccentric link mechanism, strong spring mechanism, two-position four-way valve, limit switch, pressure gauge and so on.

After the motor is decelerated by the worm gear, the eccentric wheel 2 drives the connecting rod 3 to make a linear reciprocating motion. Due to the action of the spring mechanism 4 linked to the end of the connecting rod, the sliding core rod 6 in the two-position four-way valve 5 has a rapid push-pull action, thereby changing the connection manner of the oil ports of the two-position four-way valve to achieve liquid flow The purpose of commutation. At this time, the eccentric rotates 180 ° to reach another dead point position, and the limit switch 7 is triggered. The limit switch can send out a pulse signal to stop the valve motor and complete a working process. A pressure gauge 8 is installed on the top of the protective cover 9 for monitoring the working pressure inside the valve.

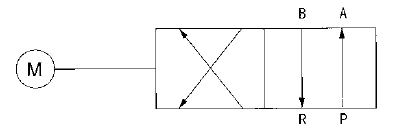

IV.Graphic symbol

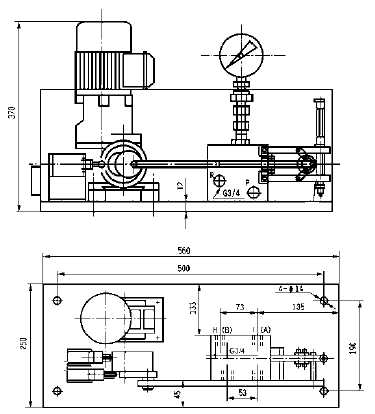

V.Dimensions

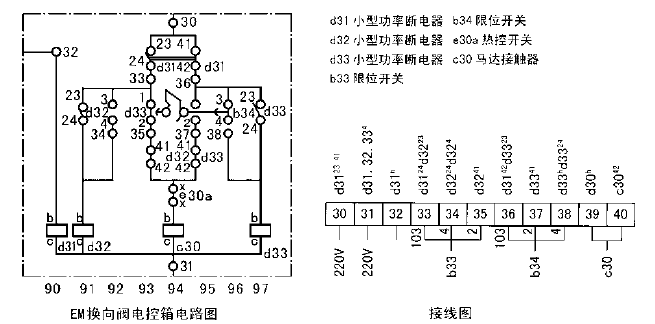

VI.Circuit diagram and wiring diagram of EM reversing valve electric control box

VII.Instructions for use

The valve should be installed at the front end of the main pipeline of the system, and it should be located in a place that is ventilated, dry, easy to inspect and free from interference of the surrounding movement mechanism. Before use, the outer cover must be opened to add 50 # mechanical oil to the specified liquid level.

Address: No.010 Xinglong Road, Huilong Industrial Park, Qidong City

Hotline:0513-83637668

Company Fax:0513-83637098

After sales service:0513-83635700

URL:www.qdhsrh.com

Website :en.qdhsrh.com

E-mail:qd3637668@163.com

Scan to learn more