I. Overview

24EJF-M (formerly SA-V) two-position four-way reversing valve is an integrated reversing control device that uses a DC motor to drive the spool to open and close the fuel supply pipe or change the fuel supply direction ; Even under severe working conditions (such as low temperature or high viscosity grease), the action is still quite reliable.

This valve is suitable for dry and thin oil centralized lubrication system and main branch pipeline of hydraulic system with nominal pressure below 40M P a. It can also be used as two types of four-way, two-position three-way and two-position two-way.

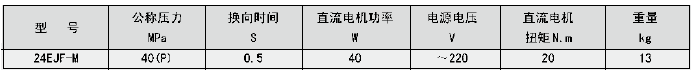

II.Technical Parameters

Use medium with a cone penetration of not less than 220 (25 ° C, 150g) 1 / 10mm grease (NLGI 0 # ~ 3 #) or a lubricant with viscosity class greater than N68, working environment,The temperature is -20 ° C to 80 ° C.

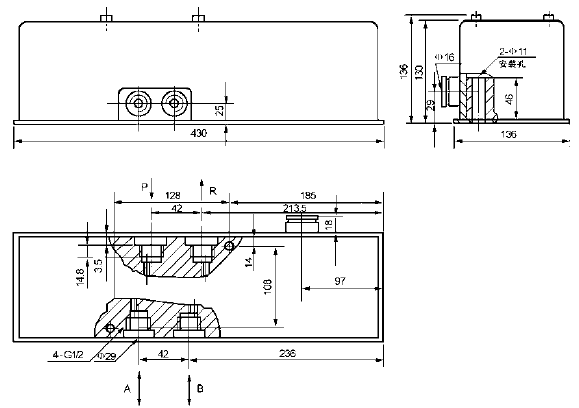

III.Dimensions

IV.Working principle

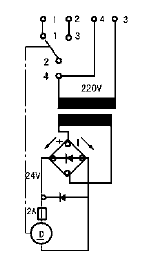

The valve is mainly composed of DC motor, limit switch, reversing valve body, rectifier transformer device and other components. It is installed on the same base plate and placed in a protective cover.

The electric control box in the system sends a commutation signal (issued by the differential pressure switch at the end of the system) to make the DC motor rotate, and the eccentric wheel drives the valve core to make a linear reciprocating motion. When the valve core reaches the required reversing position from the original position, the baffle at the end of the valve core triggers the limit switch to send an electric signal to the electric control box, instructs the DC motor to stop rotating, and completes the commutation process.

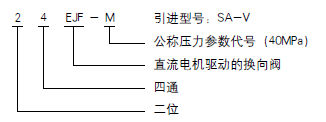

V.Model Description

VI.Instructions for use

1. The valve should be installed at the front end of the main and branch pipes of the system, and it should be located in a place that is easy to check and ventilated and dry, and there is no interference from the movement mechanism. Process lubrication manufacturing

2. When used as a two-position two-way, the oil outlet “B” and the oil return “R” must be blocked.

3. When used as a two-position tee, the oil outlet "B" must be blocked.

4. The electric control wiring is connected according to the principle on the right.

VII.Common faults and troubleshooting methods

1. The reversing valve is not reversing.

There may not be a commutation signal input to the motor, and the wire pins are welded off; the motor shaft and the eccentric are loose and not fastened; the foreign matter in the valve cavity enters the sliding core and is stuck, and other reasons can be eliminated after investigation.

2. There is oil leakage at the two ends of the sliding core.

It is mainly caused by the damage of the two-end seals. It may be that the seals have been in stock for a long time or have been used for a long time. Replace the seals.

Address: No.010 Xinglong Road, Huilong Industrial Park, Qidong City

Hotline:0513-83637668

Company Fax:0513-83637098

After sales service:0513-83635700

URL:www.qdhsrh.com

Website :en.qdhsrh.com

E-mail:qd3637668@163.com

Scan to learn more