I. Overview

It is used for electric terminal centralized lubrication system, which sends the lubricant output from the lubricating pump to the two main oil supply pipes alternately. The valve has a pressure regulating function and can automatically switch the direction. It is easy to adjust, and the structure is simple, and the commutation is reliable.

II.Working principle

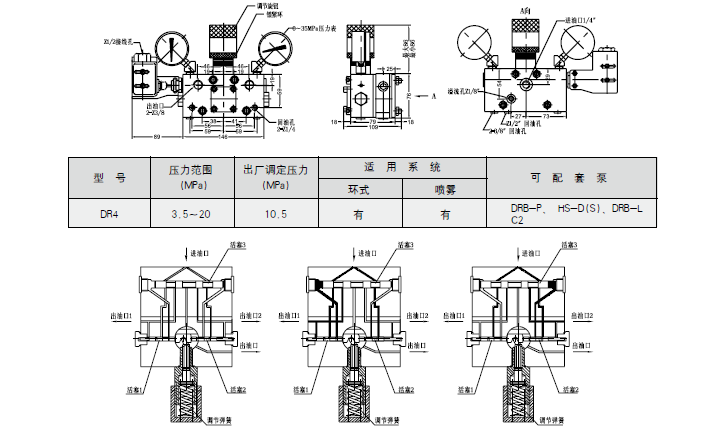

The oil chamber passage of the valve is shown in Figure 1. At this time, the force of the pressure regulating spring acts on the piston 1 via the dial block, so that the piston 1 is on the left side of the valve body. The ends of piston 1 and piston 2 are in communication with oil outlet 1 and oil outlet 2, respectively.

The pressure oil enters the two chambers of the piston 3 from the oil inlet (Figure 2), where the pressure oil in the left chamber flows out through the oil outlet 1, and at the same time, the pressure oil acts on the left end of the piston 3 through the internal cavity of the piston 1, so that the piston 3 On the right side of the valve body, the right side of the piston 3 is in communication with the oil return port at this time. The pressure oil in the right cavity is sealed by the piston 2. When the pressure at the left end of the piston 1 (outlet pressure) overcomes the force of the spring on the piston, the piston 1 moves to the left, while the piston 2 moves to the left.

When piston 1 and piston 2 move to the right end of the valve body (Figure 3), the left side of piston 3 communicates with the oil return port. Pressure oil acts on the right side of piston 3 through the internal cavity of piston 2 and pushes the piston to the left to reach the valve. Body left. At this time, the pressure oil in the right cavity of the piston 3 flows out through the oil outlet 2, and the pressure oil at the left end is sealed by the piston 1. When the pressure at the right end of the piston 2 (outlet pressure) overcomes the effect of the spring on the piston, it is lubricated with dry thin oil, the piston 2 moves to the right, and the piston 1 moves to the right. When piston 1, piston 2 moves to the left end of the valve body, the right side of piston 3 communicates with the oil return port, and pressure oil acts on the left side of piston 3 through the internal cavity of piston 1, pushing the piston to the right to the right side of the valve body ( Figure 1), complete a work cycle.

Note: If you want to check the reversing condition of the hydraulic valve, you can install a reversing transmitter on the valve. When the high-pressure oil outlet turns from "oil outlet 1" to "oil outlet 2", the piston in the valve moves, so that The contacts in the transmitter are closed. When the piston moves in the opposite direction, the contacts are opened. The user can connect the transmitter to the controller or monitoring device as required. In addition, on-site operators can directly observe the movement of the indicating rod through the transparent tube on the transmitter.

Address: No.010 Xinglong Road, Huilong Industrial Park, Qidong City

Hotline:0513-83637668

Company Fax:0513-83637098

After sales service:0513-83635700

URL:www.qdhsrh.com

Website :en.qdhsrh.com

E-mail:qd3637668@163.com

Scan to learn more