I. Conditions of use

This product is suitable for thin oil circulating lubrication system. Its working medium is steam turbine oil, 20-25 mechanical oil and rolling mill oil. The kinematic viscosity grade is N22 ~ N460 (equivalent to ISO VG22 ~ VG460).

The nominal oil supply pressure of the thin oil station is 0.63MPa; the filtering accuracy is 0.08 ~ 0.12mm; the cooling water temperature is ≤28 ℃; the cooling water pressure is 0.2 ~ 0.3MPa; the oil inlet temperature of the heat exchanger is 50 ℃, and the temperature drop is 7 ~ 8 ℃; When using steam heating, the steam pressure is 0.2 ~ 0.4MPa.

II.Working principle

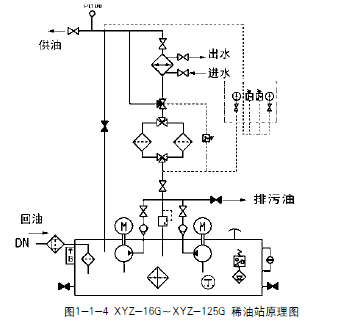

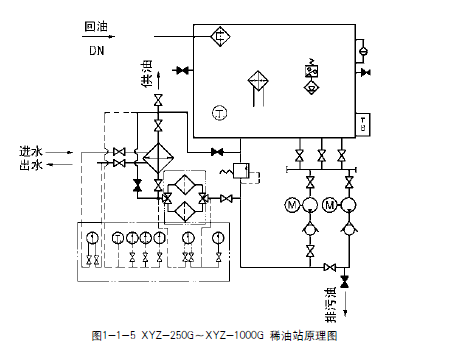

During operation, the oil is sucked out of the oil tank by the gear pump, and is directly sent to the process lubrication point of the equipment through the check valve, double-cylinder oil filter, and tubular oil cooler. The high oil supply pressure of the petrol station is 0.4MPa and the low oil supply pressure is 0.1MPa. According to the requirements of the lubrication point, the operating pressure is set by adjusting the safety valve. When the working pressure of the oil station exceeds the set pressure of the safety valve, it is safe The valve will open automatically and excess oil will flow back to the tank. During normal operation, one oil pump works and one spare. Sometimes when the fuel consumption of the equipment needs to increase for some reason, the system pressure drops. When it reaches the set value, it is adjusted by the pressure controller. The standby pump automatically starts and works with the working pump until the pressure is normal. Automatic stop. If the oil pressure continues to fall to another setting value, it is adjusted by another pressure controller to issue an accident alarm.

One set of filter elements of the double-barrel oil filter works, one set of filter elements is used for backup, and a differential pressure transmitter is connected at the inlet and outlet. When the pressure difference exceeds 0.15MPa (≥250L / min thin oil station is 0.15 ~ 0.1MPa) , Manual switching, spare filter element work, take out the original working filter element, clean or replace the filter.

The oil outlet of the petrol station is connected with a pressure-type electric contact thermometer. According to the requirements of the fuel supply temperature, two limits are set: high and low. When the temperature is low, the signal light is on, and the heater is manually turned on for heating. When the oil temperature rises to a high point, the heater is automatically turned off to stop heating. When the temperature of the oil supply port is high, the alarm is turned on and the cooler is turned on.

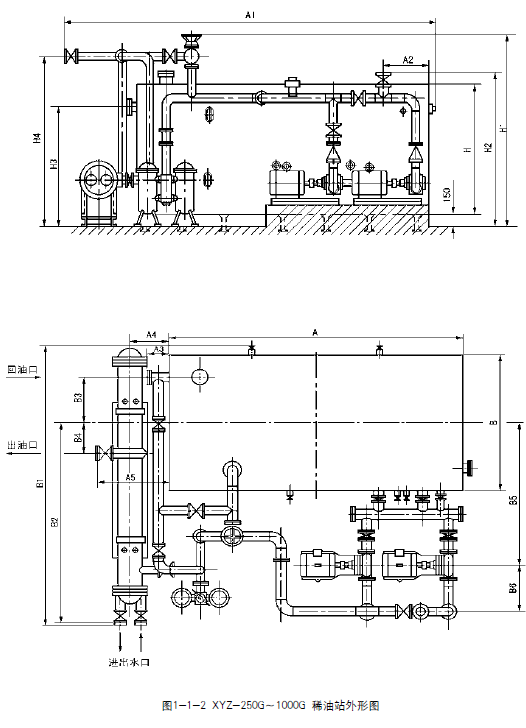

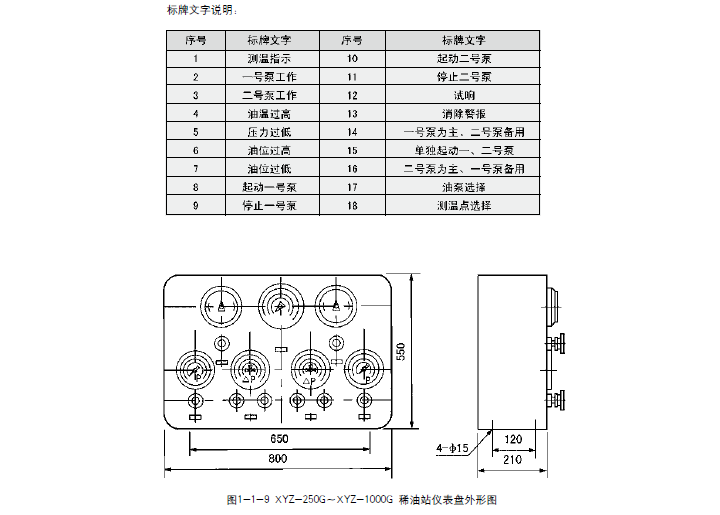

≥250L / min thin oil station uses steam to heat the lubricating oil in the oil tank. There is one more instrument on the instrument panel to detect the pressure difference between the inlet and outlet pipes of the cooler. Its main components are additionally installed on the foundation; and ≤125L / min thin oil station All the components are mounted on the fuel tank and have a unitary structure.

III.Structural features

a) A backup oil pump is provided to ensure continuous oil supply to the lubrication point.

b) The filter is placed in front of the cooler, which can improve the filtering and passing capacity; it is more suitable for higher viscosity lubrication media.

c) The double-barrel filter can be used to clean and replace the filter element without stopping.

d) The tube-type oil cooler is adopted, which has low resistance and is easy to maintain.

e) The magnetic return filter is equipped with a magnetic mesh filter, which can adsorb and remove ferrite particles in the oil to ensure the cleanliness of the oil and reduce the wear of the lubricating components.

f) Equipped with instrument panel and electric control box, it is convenient to observe the operating parameters, and it can realize automatic control and accident alarm.

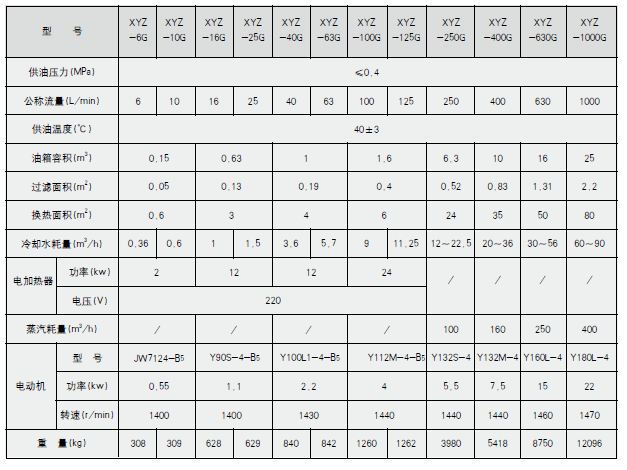

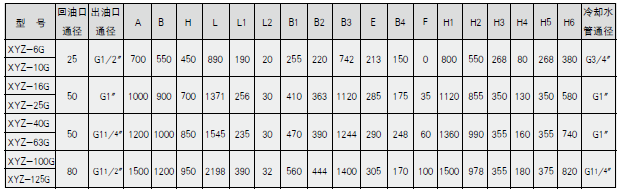

IV.Technical Parameters

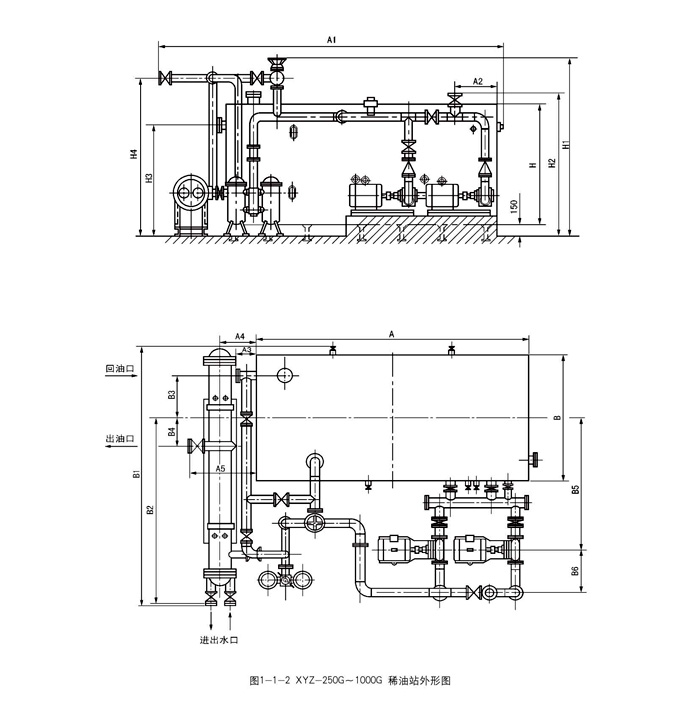

V.Outline

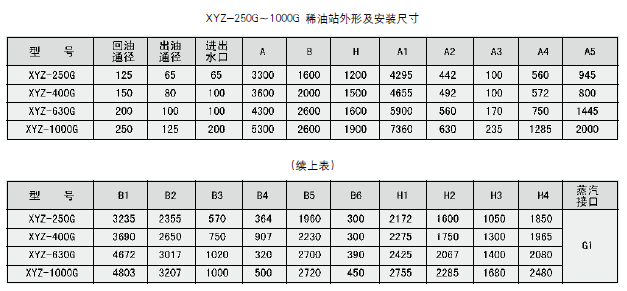

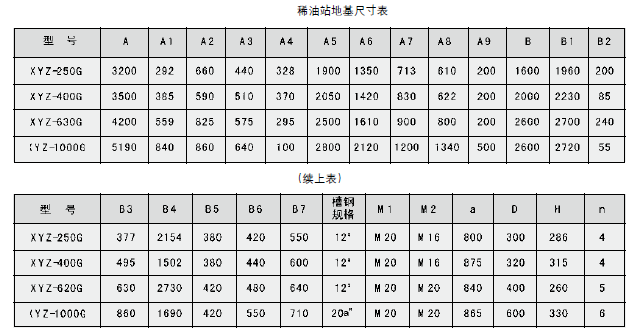

VI.Dimensions

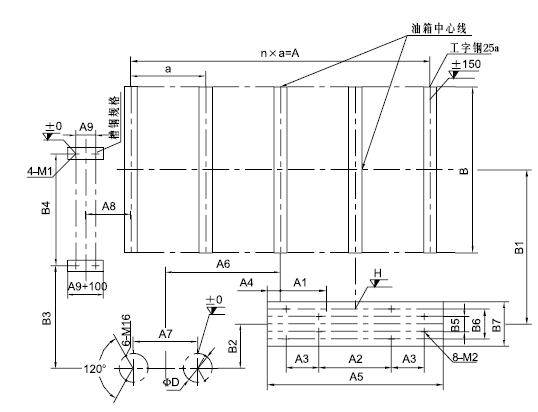

VII.XYZ-250G ~ 1000G thin oil station foundation size

图1-1-3 XYZ-250G~1000G 稀油站地基图

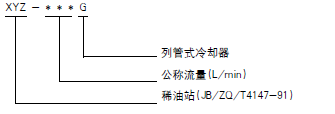

VIII.Model marking method

IX.Principle diagramFigure

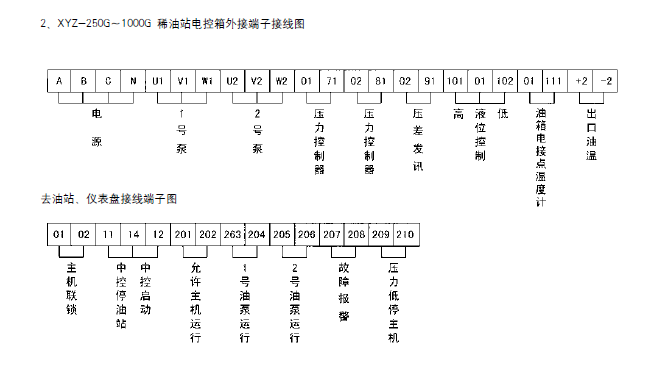

X.External wiring diagram

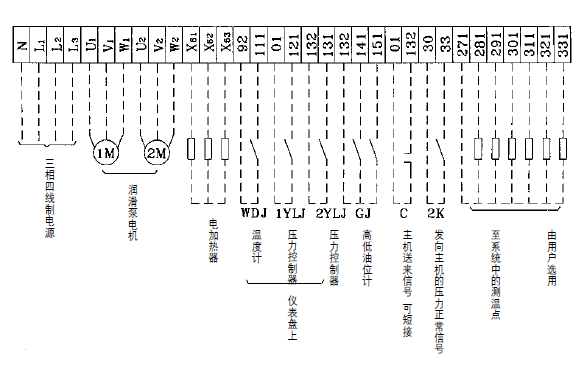

XYZ-6G ~ 125G Wiring diagram of external terminal of electric control box of thin oil station

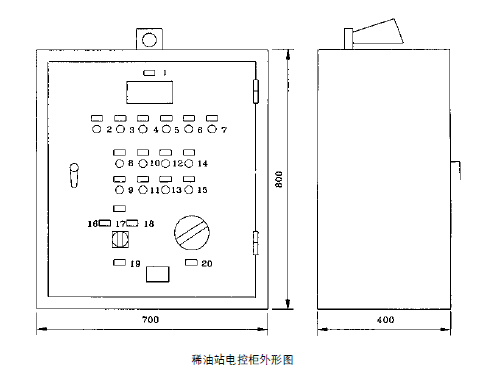

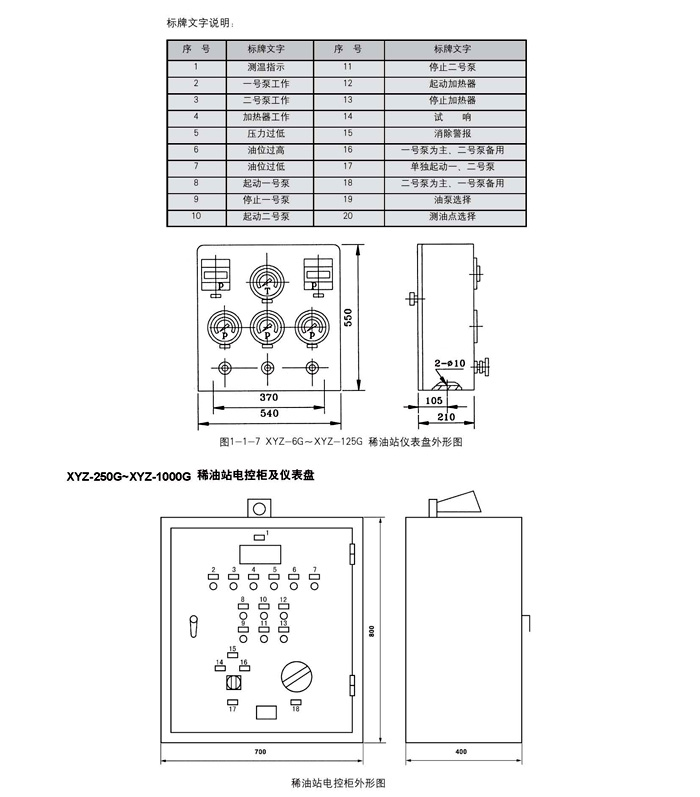

XI.Electric control cabinet, instrument panel

XII.Ordering instructions

1. Example of order mark:

If you order the above JB / ZQ / T4147-91 standard thin oil station, it will be marked as follows:

For example: a thin oil station ordered with a nominal flow of 125L / min is marked as:

XYZ-125G Thin Oil Station (JB / ZQ / T4147-91)

If ordering a thin oil station with a nominal flow of 400L / min without a cooler

XYZ-400A Thin Oil Station (JB / ZQ / T4147-91)

Note: "A" replaces "G" as a thin oil station without a cooler.

2. If the heat exchanger uses a plate cooler, please specify in the order contract. The outline drawing and the size of the foundation need to be changed accordingly.

3. The standard thin oil station is supplied as a complete set, with electrical control cabinet and instrument panel. If there is no electrical control cabinet or instrument panel, please specify in the order contract: if PLC control is required, please also specify and negotiate separately according to requirements

4. The oil grade and viscosity of the thin oil station, and the filtration accuracy should also be specified. If the filtration accuracy is higher than 0.08mm or the material of the filter element is required, the price should be changed accordingly.

5. If there are special requirements for thin oil stations, non-standard orders should be made and the price determined through negotiation.

Address: No.010 Xinglong Road, Huilong Industrial Park, Qidong City

Hotline:0513-83637668

Company Fax:0513-83637098

After sales service:0513-83635700

URL:www.qdhsrh.com

Website :en.qdhsrh.com

E-mail:qd3637668@163.com

Scan to learn more