I. Conditions of use

This product is suitable for the thin oil circulating lubrication system of large equipment such as mills, rotary kiln and other equipment equipped with double-slide dynamic and static pressure bearings. Its working medium viscosity grade is N22.

N460 (equivalent to I S O V G22 ~ 460) various industrial lubricating oils; if the amount of low-pressure pump oil is divided into two oil supply pipes, a set of double high-pressure high (low) pressure can be used to dilute

Gas stations replace two ordinary high (low) pressure thin oil stations [such as the smaller of the GXYZ type A series high (low) pressure thin oil stations].

According to the working principle of dynamic and static pressure lubrication, a high-pressure system is used at startup, low speed and shutdown, and a low-pressure system is used during normal operation to ensure that large machinery is in a variety of different

Reliable process lubrication can be obtained at speeds to extend the life of the host.

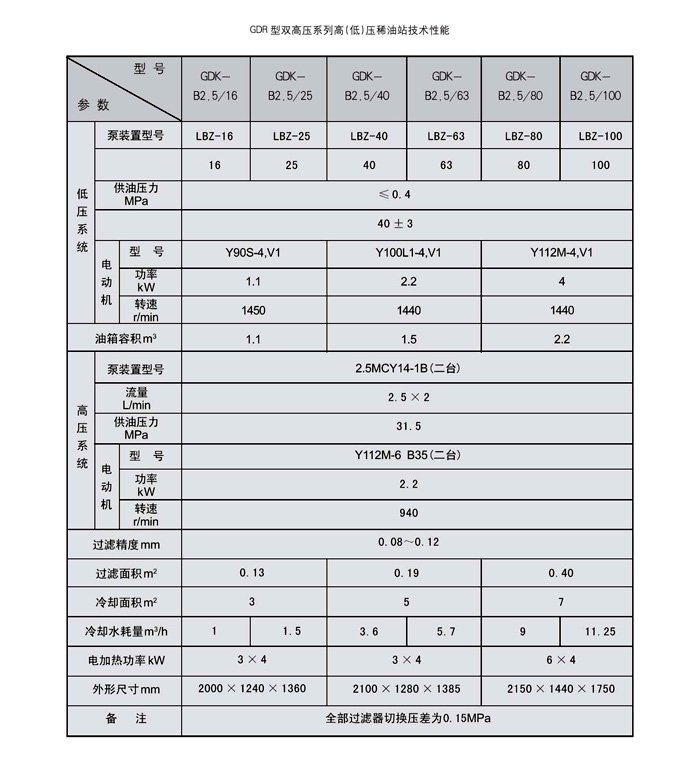

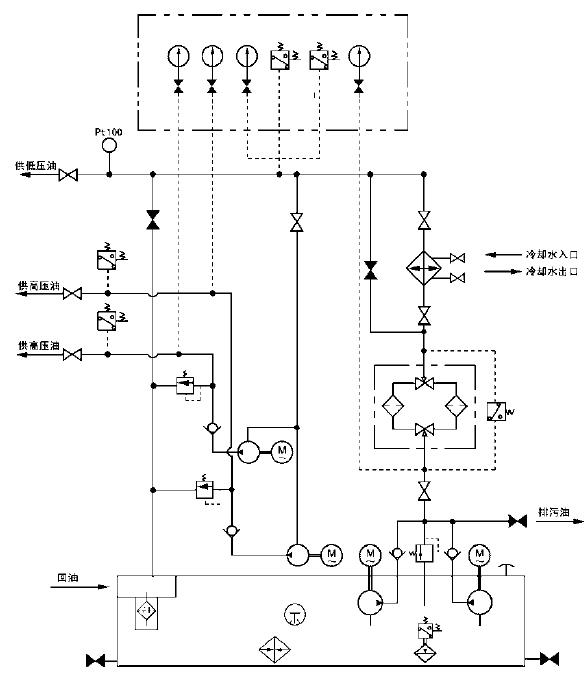

The pressure of the two high-pressure output pipes of the thin oil station are 31.5M Pa, the flow is 2.5L / m i n, the pressure of the low-pressure part is 0.4M Pa, and the low-pressure flow is 16 ~100L / min; thin oil station has filtering, cooling, heating and other devices and interlocking, alarm, automatic control and other functions.

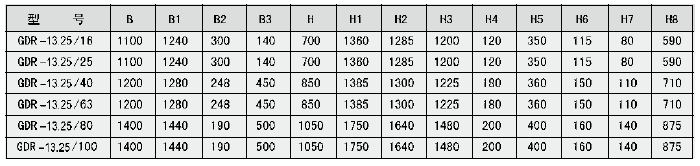

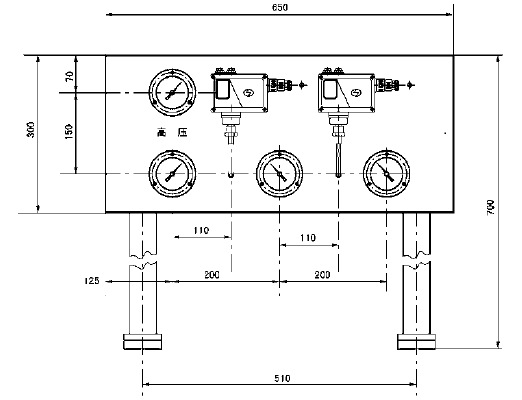

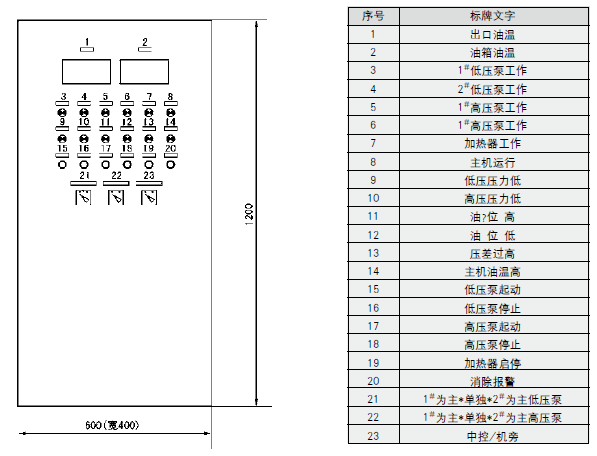

The performance parameters and dimensions of the product should meet the requirements in the table and figure; this device is composed of a gas station, an instrument panel and an electrical control cabinet (which can be controlled by PLC).

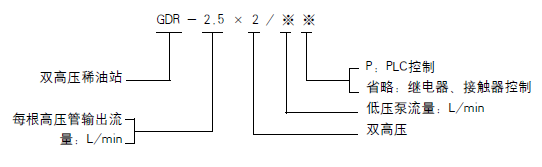

II.Model marking method

III.Working principle and structural characteristics

The main feature of the dual high pressure high (low) pressure thin oil station is that a set of thin oil stations has two high pressure output pipelines, which can meet the needs of two high pressure lubrication points. Others are the same as ordinary high (low) pressure thin oil stations.

Each high-pressure output pipeline has a pressure gauge and a pressure controller in order to control the pressure of each high-pressure pipeline and observe the working conditions.

The components of this product are also the same as ordinary high (low) pressure thin oil stations; there is only one more high pressure oil pump, and the suction ports of the two high pressure oil pumps are connected to the oil supply ports of the low pressure pumps. When both high pressure pumps are started, It is necessary to suck 5L / min of lubricating oil from the low-pressure oil supply port. For the low-pressure pump flow, the low-pressure oil supply pressure may be reduced when the high-pressure pump is started. For the system where the lubricating oil is supplied to the same bearing, The total amount of lubricating oil in the bearing has not decreased, and it will not affect the lubrication of the bearing. However, when the high-pressure pump is started, the decrease in low-pressure pressure may cause the temporary low-pressure pump to start temporarily, which will not affect the normal operation of the lubrication system; When using the backup mode where the two low-pressure pumps switch to each other, it may not be possible to make the lubrication system work normally when the standby pump flow still does not meet the requirements after the working pump is stopped; therefore, this situation should be paid attention to when selecting a low-flow low-pressure pump.

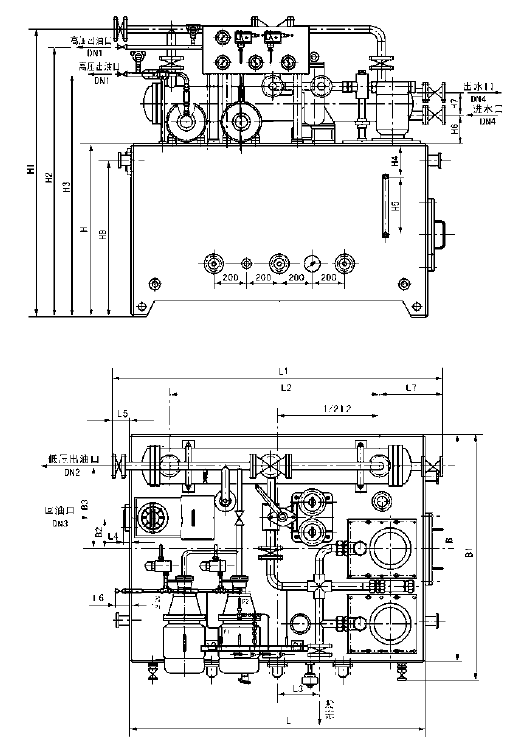

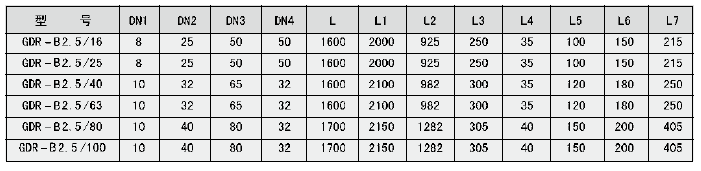

IV.Dimensions

V.System (principle) diagram

VI.Dash board

VII.Electric control cabinet

Address: No.010 Xinglong Road, Huilong Industrial Park, Qidong City

Hotline:0513-83637668

Company Fax:0513-83637098

After sales service:0513-83635700

URL:www.qdhsrh.com

Website :en.qdhsrh.com

E-mail:qd3637668@163.com

Scan to learn more