I. Conditions of use

This product is suitable for thin oil circulating lubrication systems with large equipment such as mills, rolling mills, and motors equipped with dynamic and static pressure bearings. Its working medium is various industrial lubricants of N22 ~ N320 (equivalent to ISO VG22 ~ VG320).

According to the working principle of dynamic and static pressure lubrication, a high-pressure system is used during startup, low speed and shutdown, and a low-pressure system is used during normal operation to ensure that large machinery can obtain reliable lubrication at various speeds to extend the life of the host.

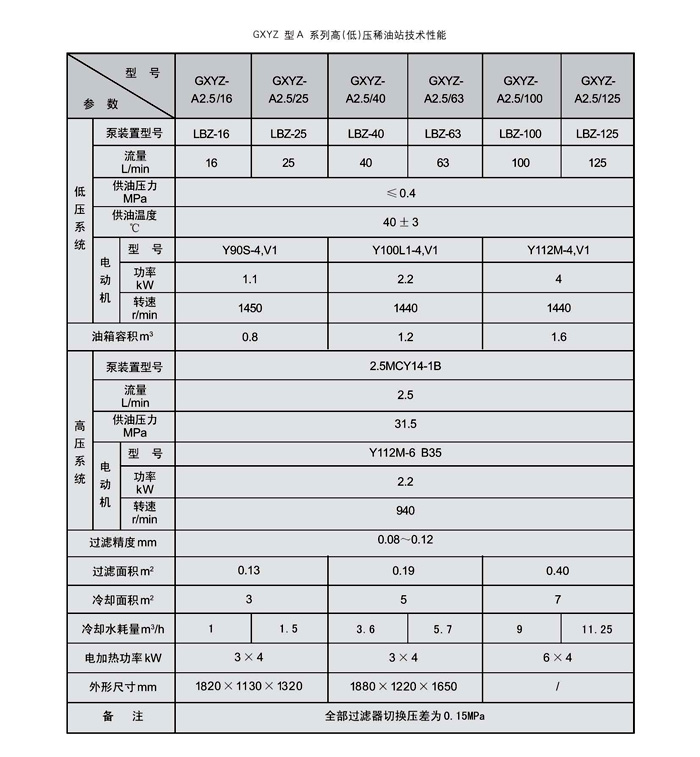

The pressure of the high pressure part of the thin oil station is 31.5MPa, the flow rate is 2.5L / min, and the pressure of the low pressure part is 0.4MP a; the flow rate is 16 ~ 125L / min. The thin oil station has filtering, cooling, heating and other devices, interlocking and alarming. , Automatic control and other functions.

The performance parameters and dimensions of the product should meet the requirements in the table and figure; the device is composed of a gas station, an instrument panel, and an electric control cabinet (which can be controlled by PLC).

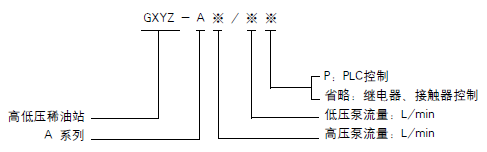

II.Model marking method

If A series is used, the high-pressure flow is 2.5L / min; the high-pressure is 31.5MPa, and the low-pressure fuel supply pressure is 0.4MPa; while the low-pressure fuel supply is 40L / min for high (low) pressure thin oil stations, which is controlled by PLC It is marked as follows: GXYZ-A2.5 / 40.P

III.Structural features

This product is mainly composed of a fuel tank (with a magnetic mesh filter inside), a low-pressure oil pump device, a high-pressure oil pump device, a double-cylinder mesh filter, a manual high-pressure oil pump, a cooler, a pipe, a valve, an instrument panel, and an electric control cabinet.

Before the host starts, start the low-pressure pump. When the low-pressure oil supply pressure is normal, start the high-pressure oil pump with the suction port connected to the low-pressure pipeline. The high-pressure oil is sent to the hydrostatic bearing through the high-pressure check valve. When starting, the main engine can start, run at low speed or stop; after the main engine speed is normal, you can stop the high pressure pump (except low speed operation), the process is lubricated but the low pressure oil pump must be supplied normally; the low pressure oil pump sucks oil from the tank through the check valve Double-cylinder mesh filter and cooler also go to the static pressure bearing to maintain the normal oil supply of the host; if the host is stopped, the high-pressure pump and low-pressure pump should be regularly supplied with oil, then controlled by the time relay to the lubrication point intermittently Fuel.

The specific values of high and low pressure are controlled by low pressure safety valve and high pressure relief valve in the system, respectively.

When the host is operating normally, one low-pressure pump works and one is standby. If the system pressure drops to a certain value, the standby pump starts to run and the standby pump stops when it reaches normal pressure. If the pressure drops to a lower value after the standby pump is started, an alarm signal should be issued to consider the main engine stopping.

When the high-pressure plunger pump is faulty, oil can be supplied by the backup manual oil pump.

The filter is placed in front of the cooler, so that the oil with a lower viscosity passes through the filter first to improve the filtering effect. The filter works in one barrel and one barrel is reserved. It is controlled by a manual switching valve.

When the oil level in the fuel tank is too low or too high, the signal will be sent by the oil level signal. Manual refueling or stop refueling.

The oil return tank is equipped with a magnetic mesh filter, which can simultaneously filter the oil and adsorb iron particles in the oil.

When the complete set of thin oil station is delivered, it is equipped with instruments and electric control box to display the operating parameters and realize the automatic control, manual control or alarm of the thin oil station.

The oil tank is equipped with an electric contact bimetal thermometer. When the oil temperature is low, a signal is issued. The electric heater is manually turned on. When the set temperature is reached, the electric heater is automatically turned off.

The oil supply port is equipped with an electric contact pressure type thermometer. According to the oil supply temperature, two limits are raised and lowered to control the use of the cooler.

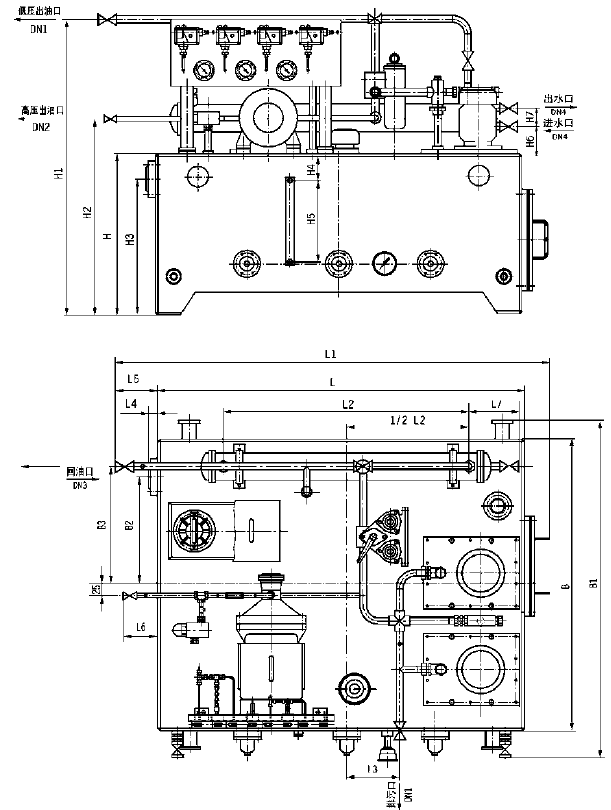

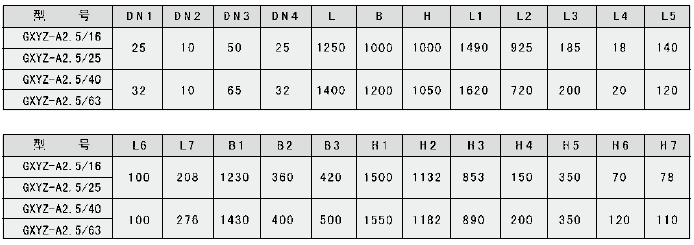

IV.Dimensions

GXYZ Type A Series Thin Oil Station Dimensions

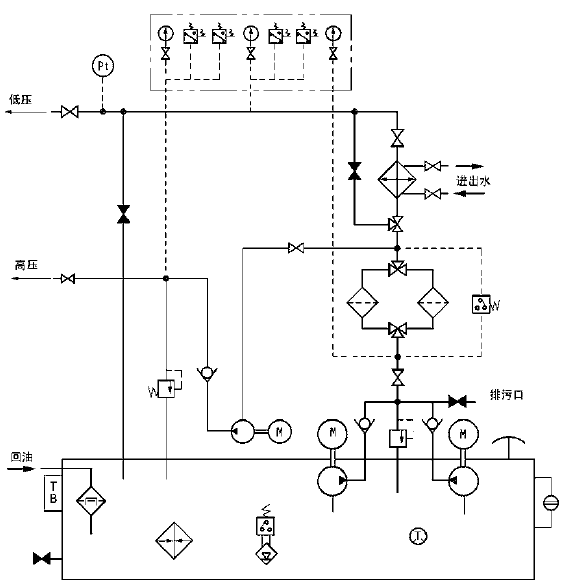

V.Principle diagram

Figure 2-1-2 Schematic diagram of GXYZ type A series thin oil station

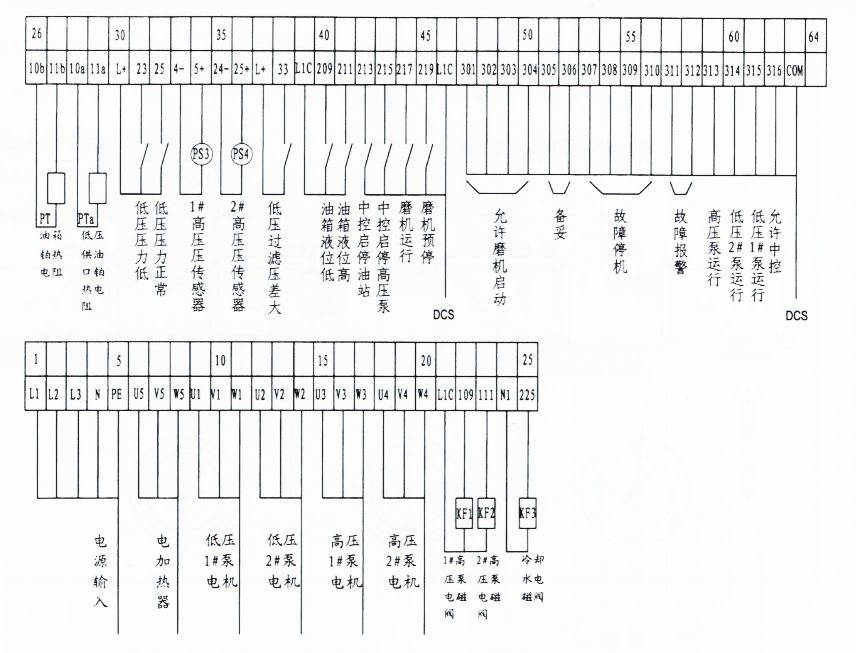

GXYZ型外部端子接线图

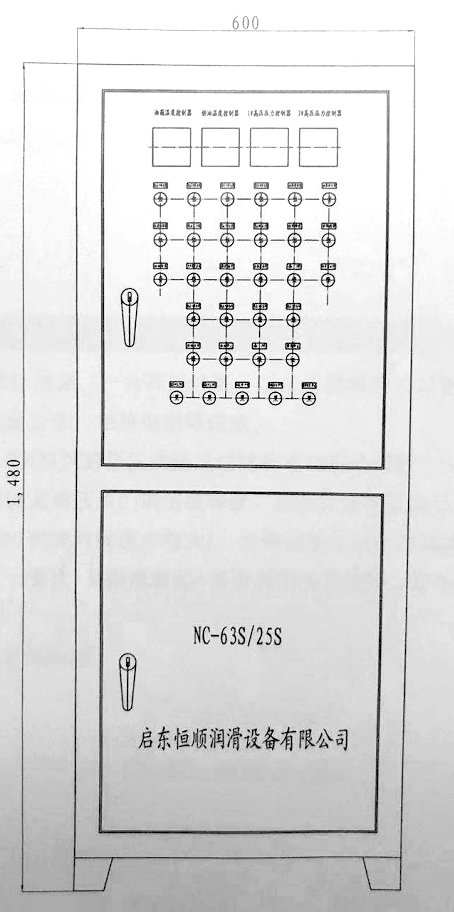

VI.Electric control cabinet

Address: No.010 Xinglong Road, Huilong Industrial Park, Qidong City

Hotline:0513-83637668

Company Fax:0513-83637098

After sales service:0513-83635700

URL:www.qdhsrh.com

Website :en.qdhsrh.com

E-mail:qd3637668@163.com

Scan to learn more