1. Overview

DRB-J series electric lubricating pump is suitable for dual-line injection centralized lubrication system with nominal pressure of 10M Pa. The oil pressure automatically opens the one-way valve of the compressed air line to spray the lubricating oil in the form of oil and gas mist onto the friction parts of the machinery and equipment. It is especially suitable for the lubrication of the friction parts of the gear such as the gear tooth surface, support rollers, slide rail surfaces of the open gear transmission.

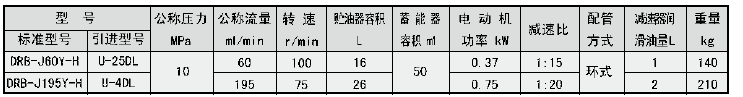

2、Technical Parameters

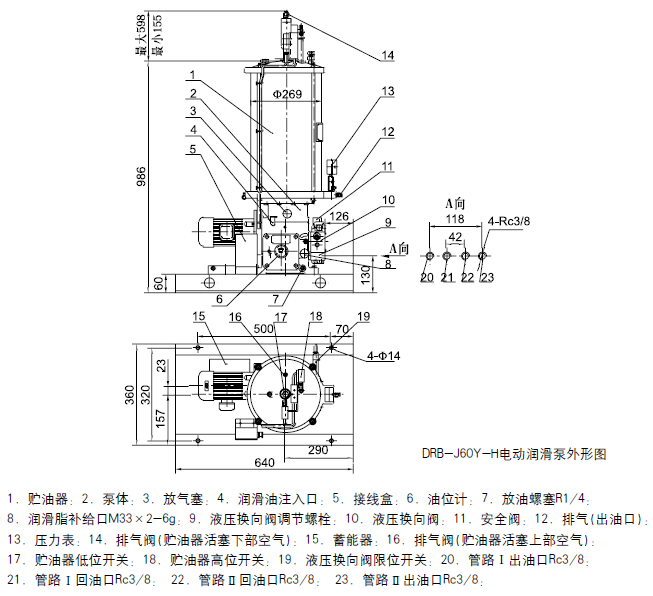

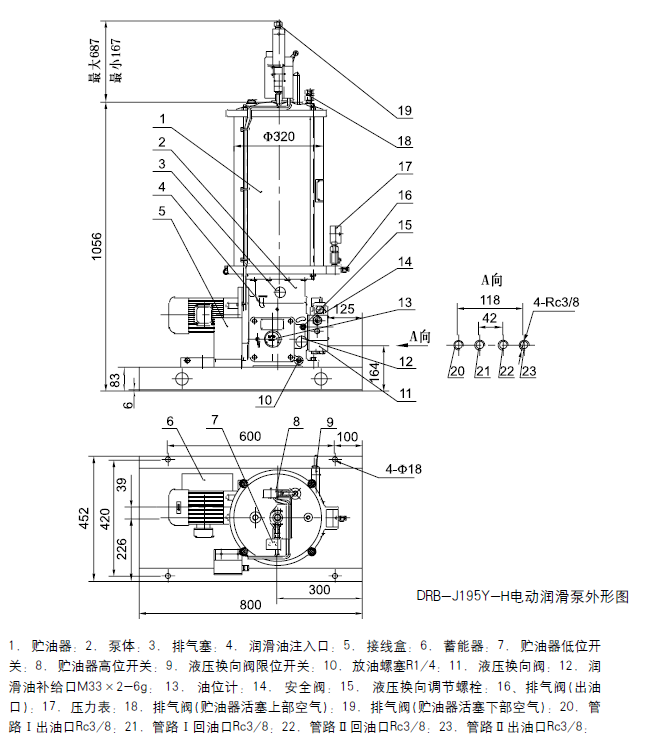

3、Dimensions

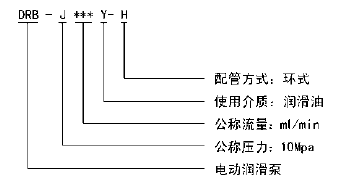

4、Model label description

5、Structure

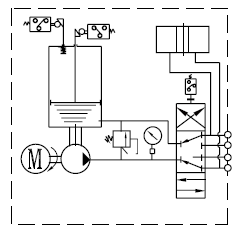

This series of electric lubricating oil pump is composed of plunger pump, oil reservoir, hydraulic directional valve, accumulator, motor and other parts. The plunger pump is driven by the electric motor, sucks the lubricating oil from the oil reservoir, and pressurizes it to the hydraulic reversing valve. The reversing valve has four interfaces. The oil return pipe relies on the pressure of the lubricating oil in the oil return pipe to push the hydraulic reversing valve to alternately transport the oil out along the two oil outlets. When one oil outlet presses the grease, the other oil outlet and the oil storage The device is connected for unloading, and the two oil ports of the accumulator are respectively connected in parallel with the two oil supply outlets of the reversing valve, so that the pipeline can be replenished in time immediately after the oil is reversed.

6、Graphic symbol

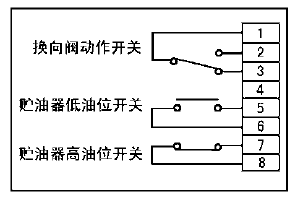

7、Wiring instructions

8.Instructions for use

1. This series of electric lubricating pumps should be installed in places where the ambient temperature is suitable, less dust, less vibration, dry and ventilated, and convenient for oil replenishment, adjustment, inspection and maintenance. If it is used outdoors or in harsh environmental conditions, protective measures should be taken.

2. To fill the oil reservoir with lubricating oil, an electric refueling pump should be used and injected from the supply port of the intelligent lubrication pump. (A filter is installed in the supply port).

3. Before the lubricating pump runs, you must fill the reducer cavity of the pump with lubricating oil (industrial gear oil N220) to reach the specified oil level. Check for replacement.

4. The rotation direction of the lubricating pump is unidirectional, and it must be used in accordance with the rotation direction specified by the rotation direction card on the motor.

5. The set pressure of the pump's relief valve can be arbitrarily adjusted within the range of 0 to 10 MPa, and it is not allowed to exceed 10% (11 MPa) of the pump's nominal pressure when in use.

6. For the working principle and common fault handling of the oil pump, please refer to the instruction manual.

Address: No.010 Xinglong Road, Huilong Industrial Park, Qidong City

Hotline:0513-83637668

Company Fax:0513-83637098

After sales service:0513-83635700

URL:www.qdhsrh.com

Website :en.qdhsrh.com

E-mail:qd3637668@163.com

Scan to learn more