1. Overview

The electric lubricating pump is suitable for single and intelligent dual-line dry thin oil centralized lubrication systems with high lubrication frequency, large piping length and dense lubrication points, as a delivery device for supplying grease. Can also be equipped with a mobile trolley, hose, oil gun and cable to form a mobile electric lubrication pump device, suitable for low lubrication frequency, less lubrication points, large oil supply, it is not convenient for centralized lubrication of single machine equipment for mobile grease lubrication. This series of lubrication pumps are electric high-pressure plungers. The working pressure can be adjusted arbitrarily within the nominal pressure range, and has double overload protection. The oil storage tank of the thin oil station manufacturer has an automatic oil level alarm device. If the lubrication pump is equipped with an electric control box, it can realize the automatic control of the two-line centralized lubrication system and supervise the system.

2.Working principle

The reduction gear motor is fixed on the connection flange with the pump device, and drives the eccentric shaft to drive the sliding fork to make a linear reciprocating motion, and drives the spiral oil pressure plate to rotate clockwise (there is no such mechanism using lubricating oil), which is softened by stirring. The grease is pressed evenly around the suction port of the pump unit. The pump has two sets of pistons. Each set of pistons consists of a working plug and two control pistons. When the working piston in one set of pistons completes the suction process, the working piston in the other set of pistons presses the grease towards the oil outlet. . As shown in the figure below, when the sliding fork moves to the left, the upper group of pistons finishes sucking oil, and the lower group of pistons finishes pressing oil to start new work. At this time, the lower groups of pistons 1 and 2 move to the left, the piston 2 reaches the position under the action of the spring force to close the exit, and the piston 1 continues to move to the left. At this time, a vacuum is formed between the pistons 2 and 1, and the degree of vacuum follows the left of the piston 1. When the movement is increasing, the sliding fork moves the piston 1 to open the oil suction port, and the grease is sucked from the oil suction port. If the spring force is insufficient, the piston 2 is not pushed. At this time, the push rod 3 will forcibly push the piston 2 under the push of the sliding fork. Press down, at the same time, the upper group pistons 1, 2, and 3 move to the left. The piston 1 first closes the oil suction port. The sucked grease moves to the left under the push of the piston 1. When the piston 2 opens the oil outlet, the piston 2 And the movement of the push rod 3 also stops, the piston 1 continues to move to the left, and the grease is pushed out from the oil outlet. The pistons 1 and 2 have also moved into contact with the fork to complete half the work. The lubricating grease is alternately sent out from the oil outlet, and the extruded grease is filtered by the filter on the connection flange of the pump device and supplied to the system.

3.The use of essentials

1. This series of electric lubricating pumps should be installed in a place with good environment and less dust, easy to adjust, check, repair and disassemble and wash, and easy to replenish.

2. This series of electric lubricating pumps should be arranged in the middle position of the system as far as possible, shorten the piping length of the system and keep the pressure drop, so that the pump can generate the pressure that can overcome the back pressure of the lubrication point.

3. The set pressure of the pump pressure regulating valve can be arbitrarily adjusted within the range of 0 to 40 MPa, and the nominal pressure of the pump (40 MPa) is not allowed during use.

4. The filter screen of the filter at the pump outlet should be cleaned regularly to prevent blockage.

5. If the pressure reaches about 50 MPa due to some failure of the series, the fuse will rupture. You must find out the cause and clean it before installing a new fuse.

6. To replenish the lubricant in the oil reservoir, you need to use the DJB-H1.6 electric grease pump to add it from the grease filling port of the reservoir.

7. The thin-film capacity indicator in the oil reservoir is only suitable for grease. When the medium is lubricating oil, it needs to be replaced with a float-type capacity indicator.

8. The electric reducer needs to be replenished with an appropriate amount of 3 # molybdenum disulfide grease from the exhaust plug hole for the first two months, and then every four months.

9. This series of electric lubricating pumps are installed indoors. When used outdoors or in harsh environments, protective measures need to be taken.

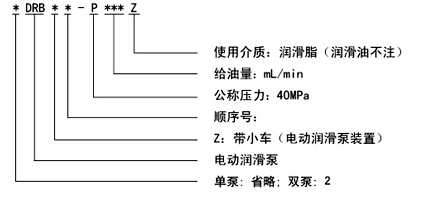

4、Model Description

Address: No.010 Xinglong Road, Huilong Industrial Park, Qidong City

Hotline:0513-83637668

Company Fax:0513-83637098

After sales service:0513-83635700

URL:www.qdhsrh.com

Website :en.qdhsrh.com

E-mail:qd3637668@163.com

Scan to learn more